Building net-zero walls, primarily from materials available in Canada’s Taiga Shield Ecozone, while honouring the building traditions of the people in this region, is a significant challenge.

What is proposed here is one approach.

If the intention is to build walls from local materials, logs are the logical material to use. However, logs present two design challenges:

-

- For a net-zero building, in this climate, a wall should have an R-value of at least 50. Because wood has an average R-value of about 1 per inch, a net-zero solid wood wall would need to be more than 4 feet thick.

- Logs crafted from trees in Canada’s Taiga Shield Ecozone are rarely more than 6 inches in diameter. And they are usually less than 15 feet long—much less than the length of logs needed in a typical log home.

Two design adjustments are needed:

-

- If made from logs, each wall will need to be built from a double row of logs, with insulation placed between the two rows.

- The interior surface of the double wall could, of course, be made of boards rather than logs, although this would require more processing of the trees, if local wood is used.

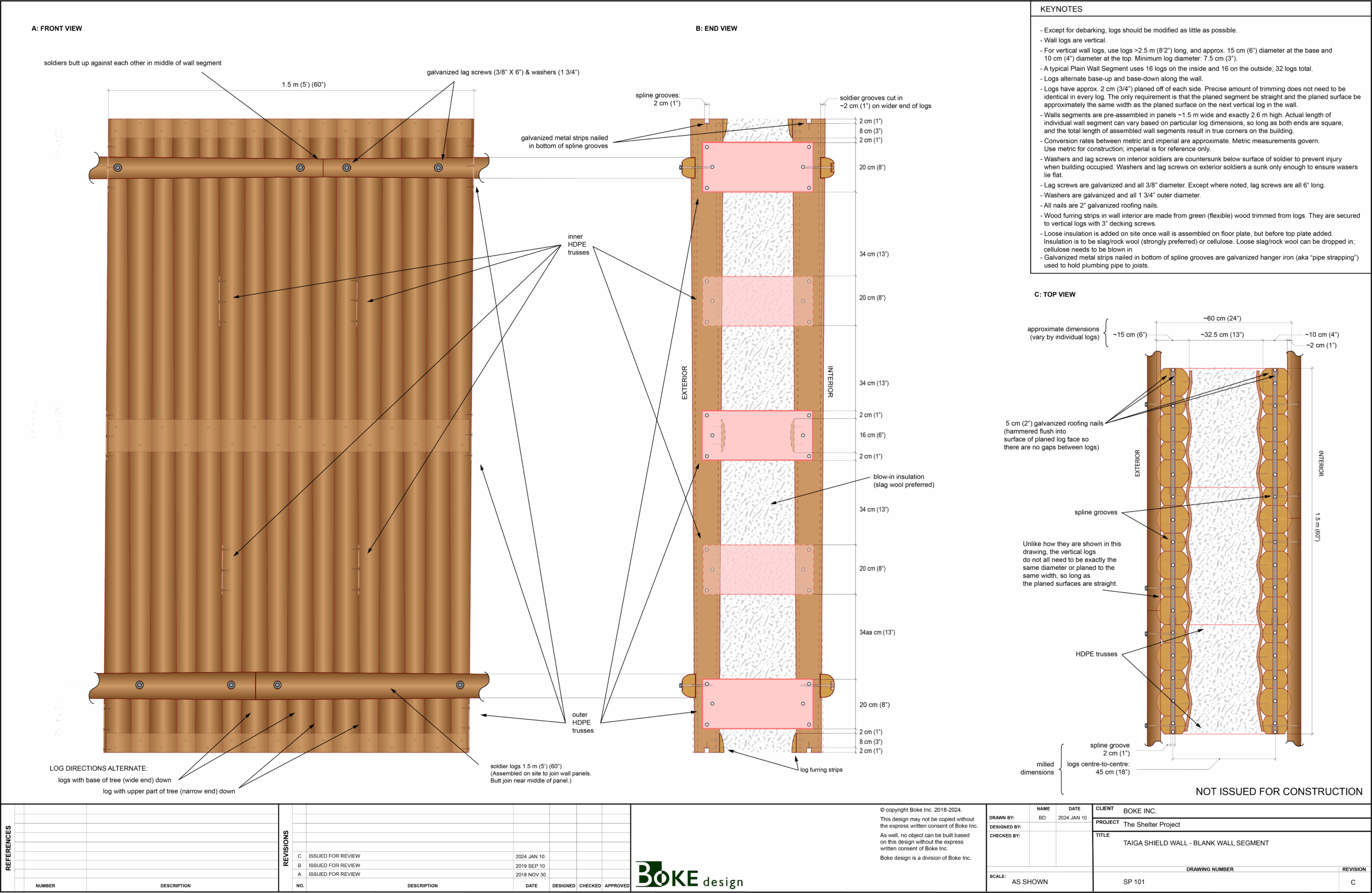

- The logs would probably need to be placed vertically, rather than the horizontal arrangement seen in many log buildings.

- If horizontal log walls are preferred, these would need to be made in segments of probably no more than 8 feet each. This approach is feasible, but not the one pursued here.

- If made from logs, each wall will need to be built from a double row of logs, with insulation placed between the two rows.

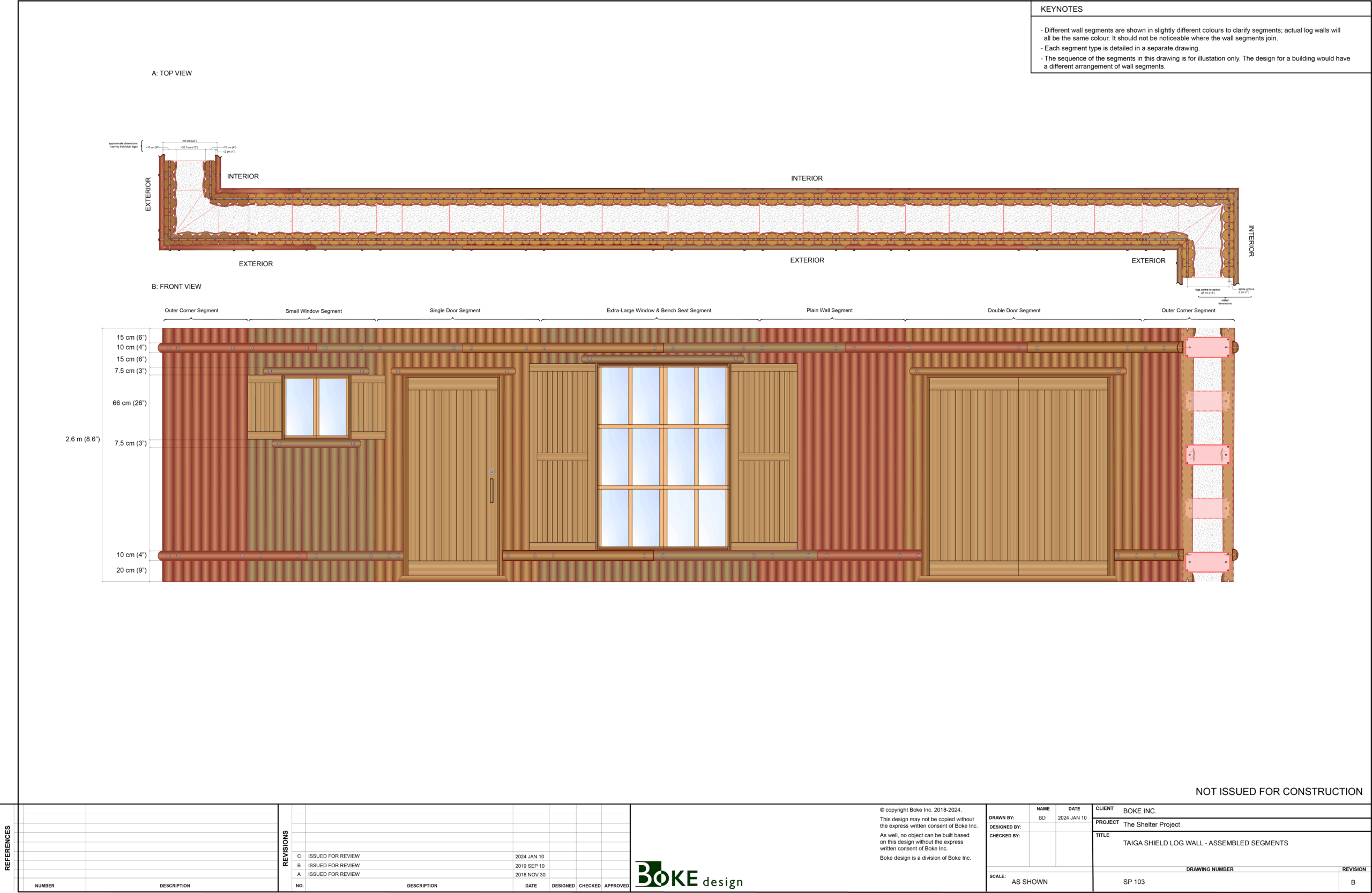

The wall segments range from 4 to 10 feet wide. They have a few basic variants:

-

- plain wall segment

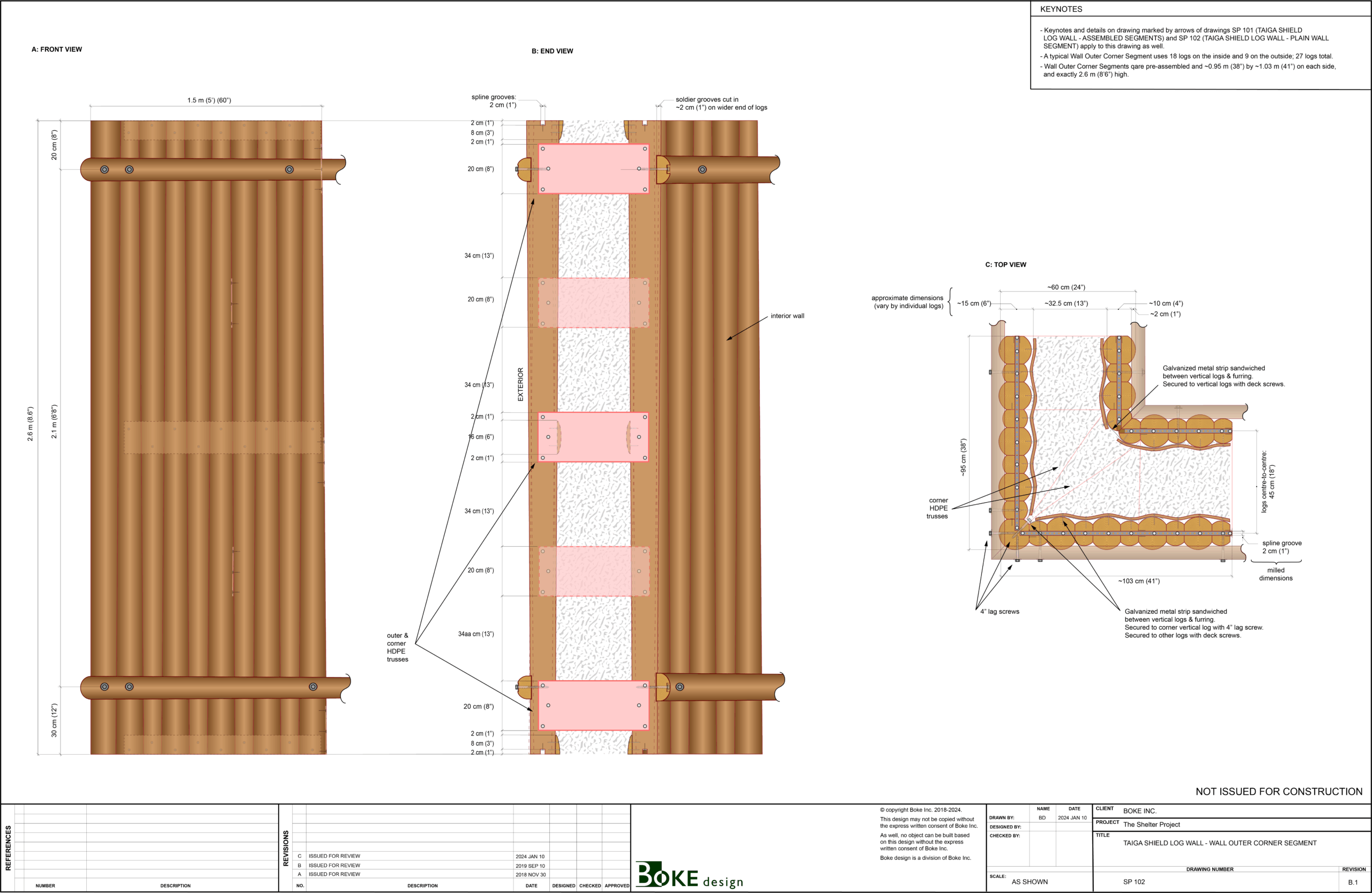

- corner segment

- small window segment

- extra-large window (with interior bench seat) segment

- single door segment

- double door segment

The inner and outer walls are held together with HDPE plastic sheets. In the drawings, they are shown in pink, although the sheets themselves are usually white. These:

-

- are food-grade, and therefore safe for people

- are very poor tansmitters of heat, and so will not act as heat bridges

- can, if builders wish, be cut from 5-gallon plastic pails, which are commonly discarded in Taiga Shield communities

The insulation proposed is blow-in slag or rock wool. This material is proposed for use in these buildings because:

-

- it has a higher R-value than fiberglass

- is easy to install with local labour

- is a mature technology already approved in building codes

- can be made from waste materials available in the region, with local labour

- does not absorb water

- will not support mold growth

- will not slump in walls and lose insulating properties if it gets wet

- will not allow rodents and insects to chew, nest or burrow through it

- is fire-proof

- is free of foam and plastics

- is usually reusable in new buildings after an old building is torn down

More detail on slag wool and its potential benefits as an insulation material in northern Canada can be found here.

A few low-cost, galvanized construction materials will be needed to be brought in to build these walls. They include:

-

- suspension pipe strapping (the metal strips on the top and bottom of the walls)

- lag screws

- washers

- roofing nails

The logs for these walls could be formed with a small portable sawmill. The walls could be built, assembled, and put in place by 2 to 4 people using simple tools.

The design proposes 13″ of blow-in insulation within the walls and a total wall width of 24″. Before this design can be finalized, a prototype building will need to be built and the effective R-value of its walls will need to be measured to determine the actual thickness needed.

This prototype building will also need to be tested to determine if a vapour barrier and an air exchange system are needed.