Tens of thousands of tonnes of scrap metal are scattered across Manitoba’s north. That scrap metal is found in many forms:

- derelict cars and trucks

- mining, oil and gas extraction equipment

- earth-moving, construction and public works equipment

- old railway, port, and airport equipment

- old shipping containers

- old oil storage tanks

- old buildings

- fridges, freezers, stoves, washers, and dryers

- dehumidifiers and air conditioners

- snowmobiles, quads, and boats

Some of this material is located in and near landfills. Some is scattered around communities. Some is left out on the land or in waterways. Most of these items were simply abandoned and many of them contain contaminants.

If this material is left in place, all these liquids will eventually leak out into the environment, contaminating the soil, water, and air.

Except for material that can be safely salvaged for local use, it all needs to be sent to the south and properly recycled.

Previous Studies & Initiatives

Numerous studies and initiatives aimed at reclaiming this material from Manitoba and other parts of the north have been undertaken. A partial list includes:

- Earthbound Environmental’s studies on:

- Scout Environmental

- Yukon River Inter-Tribal Watershed Council

- Government of Nunavut

(Other relevant material can be found under “Sources” at the end of this document.)

However, the most significant initiative in Manitoba—and perhaps the most significant in all northern Canada—is the vehicle recycling program of St. Theresa Point First Nation, led by Solomon Mason.

The St. Theresa Point Initiative

In 2011, Solomon Mason and Pinter & Associates conducted a waste stream study. This study

- analysed the waste material at St. Theresa Point through waste stream segregation

- assessed the potential for material recycling

- did a cost-benefit analysis of solid waste disposal, and

- developed a remediation plan for St. Theresa’s solid waste sites

Starting in 2013, community members began collecting derelict vehicles from all over the reserve, bringing them to the current landfill. During this first year, 1,500 vehicles were assembled. These derelict vehicles were then decommissioned and crushed.

In the three years since the crusher arrived, hundreds of vehicles have been crushed and hauled out on the winter road.

Solomon Mason and his crew are national leaders in vehicle decommissioning in remote communities.

The Keewatin Tribal Council Initiative

Keewatin Tribal Council (KTC) received Land and Economic Services Development Services Program (LEDSP) funding from Indigenous and Northern Affairs Canada (INAC) in the 2016-17 fiscal year to begin the process of collecting and safely decommissioning scrap metal, including derelict cars and trucks in KTC-member First Nations communities in northern Manitoba or collecting cars after accidents, of course if you also get injured in an accident is better to get a personal injury lawyer to help you in this case. If you require legal assistance in Sacramento, CA, find peace of mind knowing that there’s a trustworthy personal injury lawyer ready to champion your rights and offer expert guidance throughout your legal proceedings.

Funding has been received for two initial phases of this project:

- Phase 1: Training & Inventory

- Phase 2: Equipment

Boke Consulting was retained by KTC to implement both phases of this project.

Three KTC-member First Nations communities were identified as initial participants:

- Barren Lands First Nation, located on the north shore of Reindeer Lake (57°52’47”N, 101°40’16’ W), near the Saskatchewan border.

- Northlands Dënesųłiné First Nation, located on the shore of Lac Brochet (58°37’12”N101°29’11”W). Northlands Dënesųłiné is just over 80 km north of Barren Lands.

- Sayisi Dene First Nation, located on the shore of Tadoule Lake (58°42′43″N 98°28′50″W). Sayisi Dene is 100 km east of Northlands Dënesųłiné.

All 3 communities are in the northwest corner of the province. They are all isolated; the only vehicle accessibility is by winter road, typically open less than 2 months per year.

Training Venue

Teen Challenge—a social enterprise in Winnipeg—was chosen as the training venue.

The Teen Challenge shop in North Transcona was chosen because they have the experience, facility, mandate and training expertise.

Training Participants

Nine participants—3 from each community—were identified as potentially benefitting from training. All nine made the trip south and participated in the four-day training program:

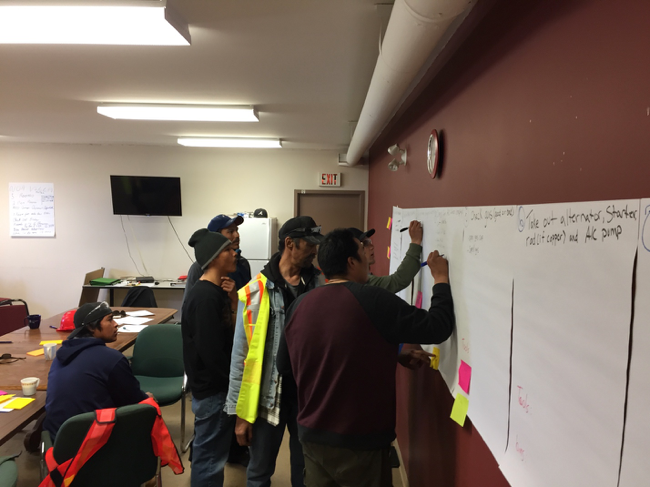

Training Process

This introductory training course focused on basic decommissioning of cars and ½-ton trucks. These activities can be summarized into 4 components:

- shop floor observation & documentation

- shop floor instruction

- hands-on shop floor work

- writing up the decommissioning process

This first component was an opportunity for the participants to closely observe a trained crew decommission a vehicle.

Instructors taught and coached participants step-by-step through the decommissioning process, with a particular emphasis on safety and environmental standards.

The participants decommissioned 6 vehicles in their 4 days of training.

In between the vehicle decommissioning, the participants, as a team, wrote up:

- a detailed listing of steps

- the equipment required for each step

- the storage containers required for each step

Next Steps

The next 5 steps are:

- setting up decommissioning equipment in these three communities

- intermediate training on the equipment in these communities

- decommissioning of derelict cars and trucks in these communities

- inventory of other derelict equipment suitable for decommissioning beyond cars and ½-ton trucks.

- recruitment of more communities for introductory training

1. Setting Up Decommissioning Equipment

Each community will need a small, fully-functioning decommissioning shop in each community. These will be smaller than the Teen Challenge shop, but will require the same basic components.

As well, the three communities will share a car crusher.

Sufficient funds were allocated in Phase 2 to enable us to purchase this equipment for all three communities.

2. Intermediate Training in the Communities

The participants in each community will require supplemental training in equipment operation and decommissioning in their new community facility. This will include:

- equipment maintenance

- review of decommissioning process

- finalization of instruction manual

- setting up and managing the storage and recycling systems

- certification in operation of the waste oil furnace

- documentation of decommissioning steps

- additional safety training

- planning for:

- business operations & record keeping

- integration with other recycling initiatives in the community

At least one person from each community will also require off-site training:

- Certification in air conditioning fluid extraction

3. Decommissioning of derelict cars and trucks in these communities

Decommissioning in these three communities can begin in 2018.

4. Inventory of other derelict equipment suitable for decommissioning

Cars and personal-use trucks do not make up the majority (by weight) of derelict equipment in these communities. In addition to white goods (fridges, freezers, stoves, washing machines, clothes dryers), dehumidifiers, air conditioners, snowmobiles, and quads, all three of these communities have significant numbers of derelict storage tanks and heavy equipment. They can fix an ac keeps short cycling. A careful inventory is required to determine what should be done with each piece of this larger equipment.

5. Recruitment of more communities for introductory training

This project was never intended to stop at just these three communities. Other northern communities can be recruited into this process.

Relevant Sources

Automotive Recyclers Environmental Association – BC. http://www.area-bc.ca.

Chesni Advisory Group. December 7, 2014. Business Plan to Establish a Waste Management & Recycling Project in St. Theresa Point First Nation. St. Theresa Point First Nation.

City of Iqaluit, Nunavut. July 28, 2015. City Landfill Accepting End-Of-Life Vehicles. http://www.city.iqaluit.nu.ca/news/end-life-vehicles-disposal-fees-various-sizes-are-available-city-iqaluit.

City of Whitehorse. August 2013. Solid Waste Action Plan. http://whitehorse.ca/departments/environmental-sustainability/waste-diversion/additional-information/solid-waste-action-plan-swap and http://whitehorse.ca/home/showdocument?id=3476

- This document is interesting, in part because, while it outlines a comprehensive plan for a wide variety of waste streams, it omits derelict vehicles.

Earthbound Environmental. 2000. A Study Into Economic Opportunities Utilizing Waste Materials In Thompson, Wabowden, and Norway House. https://bokeconsulting.com/wp-content/uploads/2017/05/Earthbound-Thompson-Waste-Economic-Opportunities-2000.pdf.

Earthbound Environmental. 2000. A Waste Diversion Strategy for the Town of Gillam. https://bokeconsulting.com/wp-content/uploads/2017/05/Earthbound-Gillam-Waste-Diversion-Strategy-2001.pdf.

Earthbound Environmental. 2003. Scrap Metal Recycling in Remote Northern Communities: A Pilot Project Implementation Plan. https://bokeconsulting.com/wp-content/uploads/2017/05/Earthbound-Remote-Northern-Metal-Recycling-2003.pdf.

ELVS, Alaska. n.d. End of Life Vehicle Solutions. http://elvsolutions.org/?page_id=404.

- Unfortunately, focused only on mercury switches.

Fisher, Ron; Hooge, Megan. April 13, 2015. “Is it time for our industry to clean up the messes in our own backyard?” Automotive Retailer. http://www.automotiveretailer.ca/paving-the-way-for-the-future/.

Government of Nunavut. January 2011. End-of-Life Vehicle Hazardous Materials Recovery Program Manual: Manual for the Preparation and Disposal of End-of-Life Vehicles in Nunavut. Prepared by Dillon Consulting Limited, Dennis Heinrichs, P.Eng., Project. http://www.gov.nu.ca/sites/default/files/final_-_elv_program_manual_-_jan_10_2011_0%20%281%29.pdf.

Hamlet of Paulatuk, NT. July 2015. Solid Waste Facility Operation and Maintenance Manual. Prepared by Jennifer Spencer of Dillon Consulting. http://doczz.fr/doc/3081725/solid-waste-facility—inuvialuit-water-board.

Hamlet of Ulukhaktok, NT. December 2015. Solid Waste Facility Operation and Maintenance Manual. Prepared by Dillon Consulting Limited, Jennifer Spencer, Project Manager. http://www.inuvwb.ca/Downloads/Public%20Registry%20pdf%20files/2015-12-23%20Solid%20Waste%20O&M%20Manual%20-%20Draft.pdf.

Indian and Northern Affairs Canada, Yellowknife, NWT. January 2007. Mine Site Reclamation Guidelines for the Northwest Territories. http://www.inuvwb.ca/Downloads/Mine_Site_Reclamation_2007.pdf.

- Section 2.9 “Buildings & Equipment” is particularly relevant to this project. This section covers “ore processing/concentrator plant, head frame, maintenance shops, offices, warehouses, fuel tanks, fuel tank farms, assay and analytical labs, process reagent and explosive storage, boiler houses, power generation plants, and camp facilities. Equipment may include: all surface and underground mobile equipment, shaft installations, distribution piping, and conveyors.” A significant portion of the non-vehicle waste in this project is like the material listed in this section of this document.

Journal of the Northern Territories Water & Waste Association. http://ntwwa.com/journal.asp.

KBL Environmental. February, 2016 & February 2017. Waste Management Plan: F-68 Well Site Remediation, Satellite Bay, Prince Patrick Island, NT. Inuvialuit Water Board. http://www.inuvwb.ca/Downloads/Public%20Registry%20pdf%20files/2017-04-13%20Updated%20WasteMgmtPlan.pdf.

- Particularly relevant to this project in that it addresses waste materials beyond vehicles, including “old fuels, batteries, scrap metal…oily rags, and impacted water”.

Machum, Eric. “Abandoned and Derelict Ships: Where do we go from here?” The Canadian Maritime Law Association. http://www.cmla.org/papers/Abandoned_Vessels.pdf.

Mackenzie Valley Land and Water Board. November 10, 2015. Operation and Maintenance Plan Templates for Municipal Water Licences: Solid Waste Facility. Mackenzie Valley Land and Water Board. https://glwb.com/sites/default/files/documents/Operation%20and%20Maintenance%20Plan%20Templates%20-%20Solid%20Waste%20Facility%20%28SWF%29%20-%20Apr%2020_17.pdf

- A useful template for developing a solid waste management plan that can include much of the materials to be managed in this project.

Mason, Solomon. April 7, 2014. Report: Scrap Metal Recycling Project Two (2) Year Action Plan April 2014 to March 2016. St. Theresa Point First Nation.

Mason, Solomon, and Pinter & Associates. March 28, 2011. Waste Stream Study, St. Theresa Point First Nation.

Scout Environmental. August, 2014. Protecting the Land – A Practical Guide to ELV Recycling in the North. http://scoutenvironmental.com/images/uploads/mainimages/TTB-Guidebook-v1aug2014.pdf.

Scout Environmental. n.d. Tundra Take-Back. http://scoutenvironmental.com/programs/tundra-take-back.

Transport Canada. November 2012. “Study of the Extent of Abandoned and Derelict Vessels in Canada.” Transport Canada. http://avicc.ca/wp-content/uploads/2013/12/TransportCanada_Report_AbandonedDerelictVesselReport_Feb202013.pdf.

Van Dusen, John. October 12, 2016. “Gov’t of Nunavut looking to charge $1,000+ to ship a vehicle North.” CBC News. Http://www.cbc.ca/news/canada/north/nunavut-considers-charging-vehicle-import-fee-1.3801501.

Wordsworth, Anne. April 2011. “Improving the Management of End-of-life Vehicles in Canada.” Canadian Environmental Law Association. http://www.cela.ca/sites/cela.ca/files/784.ELV%20April%202011.pdf.

Yukon River Inter-Tribal Watershed Council. 2016. Backhaul: A “How To” Guide. https://docs.wixstatic.com/ugd/dcbdaf_286fdf14a215417d9301c996864cbcc3.pdf.